PowerFlex spray is a high-efficiency cleaning solution designed for industrial tanks and enterprise IT equipment. Delivering 360° high-impact jets, it removes dust, residue, and contaminants from servers and storage systems, maintaining optimal performance. WECENT integrates PowerFlex spray into data center maintenance kits alongside Dell PowerFlex and PowerEdge servers, ensuring hygienic, energy-efficient, and safe cleaning for IT infrastructure.

How Does PowerFlex Spray Work?

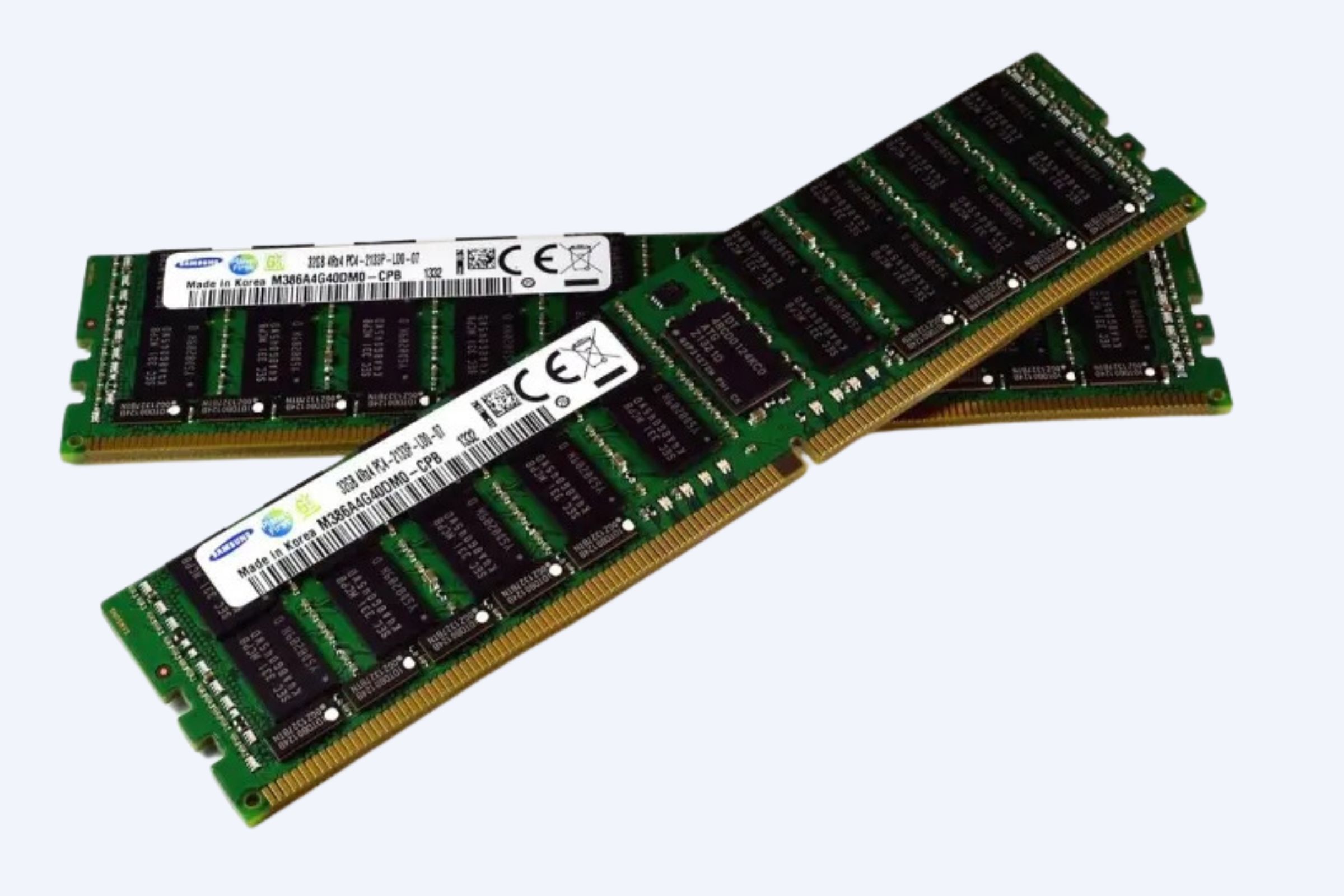

PowerFlex spray uses a combination of water pressure, high-impact jets, and 360° rotation to remove dirt and debris from surfaces efficiently. Its tangential jets dislodge dust and residue without harming sensitive electronics. In IT environments, WECENT technicians employ it to clean vents, chassis, and server racks, including NVIDIA RTX A6000 GPU arrays, ensuring optimal airflow and preventing overheating in PowerFlex storage and PowerEdge servers. Self-lubricating gears allow reliable operation even in large-scale data centers.

What Are the Benefits of PowerFlex Spray?

PowerFlex spray reduces cleaning time by up to 85%, saves water and energy, and ensures thorough hygiene compared to static methods. Portability and durable construction make it suitable for enterprise IT, healthcare, and industrial sectors. WECENT uses it to extend the lifespan of Dell, Lenovo, and Cisco servers, minimizing downtime from dust accumulation. Its Tri-Clamp and NPT connections fit diverse enclosures, protecting against corrosion in humid environments.

| Feature | IT Maintenance Benefit |

|---|---|

| 360° Jet Rotation | Comprehensive cleaning of server internals |

| Low Pressure Operation | Safe on delicate electronics |

| Self-Flushing Design | No residue in PowerFlex or PowerStore systems |

| FDA-Compliant Materials | Maintains hygiene in healthcare IT setups |

How Should PowerFlex Spray Be Used in IT Maintenance?

Secure the unit to a pressurized line via 1.5-inch threads or clamps, connect to a 40-400 psi supply, and run 360° cleaning cycles until surfaces are clean. WECENT protocols include inspecting servers like H3C switches, drying post-spray, and documenting the process for compliance. Combine with electrostatic disinfectants to prevent mold and ensure optimal airflow in data centers housing 17th-gen R770 servers or NVIDIA H100 GPUs.

Which PowerFlex Spray Models Are Recommended for Data Centers?

Gamajet PF models suit 5,000-25,000 gallon equivalents, with selection based on tank size and pressure requirements. WECENT recommends grease-lubricated variants for dusty GPU farms and standard PF models for mid-sized server rooms.

| Model Variant | Capacity | Pressure Range | IT Application |

|---|---|---|---|

| Standard PF | 5K-25K gal | 40-400 psi | PowerEdge racks |

| Grease-Lubed PF | 5K-25K gal | 50-300 psi | Dust-heavy GPU servers |

| Sanitary PF | 5K-25K gal | 40-400 psi | Healthcare IT environments |

Why Choose PowerFlex Spray Over Static Spray Balls?

PowerFlex spray delivers dynamic, high-impact cleaning that fully covers surfaces and dislodges residues static sprays miss. This reduces water usage, cleaning time, and potential downtime. WECENT highlights its effectiveness in EMC PowerScale and PowerFlex maintenance, where static balls often fail on stubborn buildup from cooling systems.

Can PowerFlex Spray Be Used on Dell PowerFlex Servers?

Yes, it safely cleans the exterior and interior of Dell PowerFlex storage systems in maintenance mode, removing dust without causing damage. WECENT includes it in custom maintenance kits for 16th-gen XE9680 deployments, maintaining airflow and performance in virtualization and AI clusters.

WECENT Expert Views

“Dust and residue accumulation in servers like Dell PowerFlex and HPE ProLiant can reduce performance by up to 30%, risking costly downtime. PowerFlex spray provides precise, high-impact cleaning to restore airflow and extend hardware life. WECENT integrates it into maintenance kits for PowerStore arrays and NVIDIA H100 GPU clusters, ensuring continuous, efficient operations across finance, AI, and cloud environments.”

— Senior IT Solutions Engineer, WECENT

How Does WECENT Enhance PowerFlex Spray Applications?

WECENT pairs PowerFlex spray with original Dell PowerFlex and PowerEdge systems, offering global delivery of customized cleaning kits. Services include OEM server support, installation guidance, and maintenance for virtualization, HCI, and cloud computing infrastructures. WECENT ensures data centers receive optimized, compliant cleaning solutions alongside hardware like PowerVault ME5 and ProLiant Gen11 servers.

Key Takeaways and Actionable Advice

PowerFlex spray provides efficient, thorough cleaning for enterprise IT, saving time and resources while protecting sensitive equipment. Recommended actions: schedule quarterly sprays for PowerEdge and PowerFlex servers, select PF models appropriate for facility size, integrate with WECENT maintenance kits, and combine with disinfectants for comprehensive hygiene. These steps preserve airflow, enhance GPU performance, and extend server life.

FAQs

Is PowerFlex spray safe for electronics?

Yes, low-pressure operation and self-flushing design prevent moisture damage when used in maintenance mode.

How often should IT teams use PowerFlex spray?

Quarterly for standard environments; monthly for high-dust or high-traffic data centers, following WECENT guidelines.

Does PowerFlex spray require lubrication?

Standard models are self-lubricating; grease-lubed versions are available for extreme conditions via WECENT.

Can WECENT supply PowerFlex spray with servers?

Yes, WECENT offers integrated kits with 14th-17th gen PowerEdge and PowerFlex storage solutions.

What is the optimal pressure range for server cleaning?

50-300 psi balances cleaning efficiency and safety for components such as NVIDIA Tesla GPUs and HPE ProLiant racks.