Stretch tape is redefining the way enterprises secure, bundle, and protect valuable equipment in logistics and IT hardware operations — delivering higher efficiency, cost savings, and enhanced reliability across global supply chains.

How Are Current Industry Conditions Creating Pressure for Better Equipment Packaging Solutions?

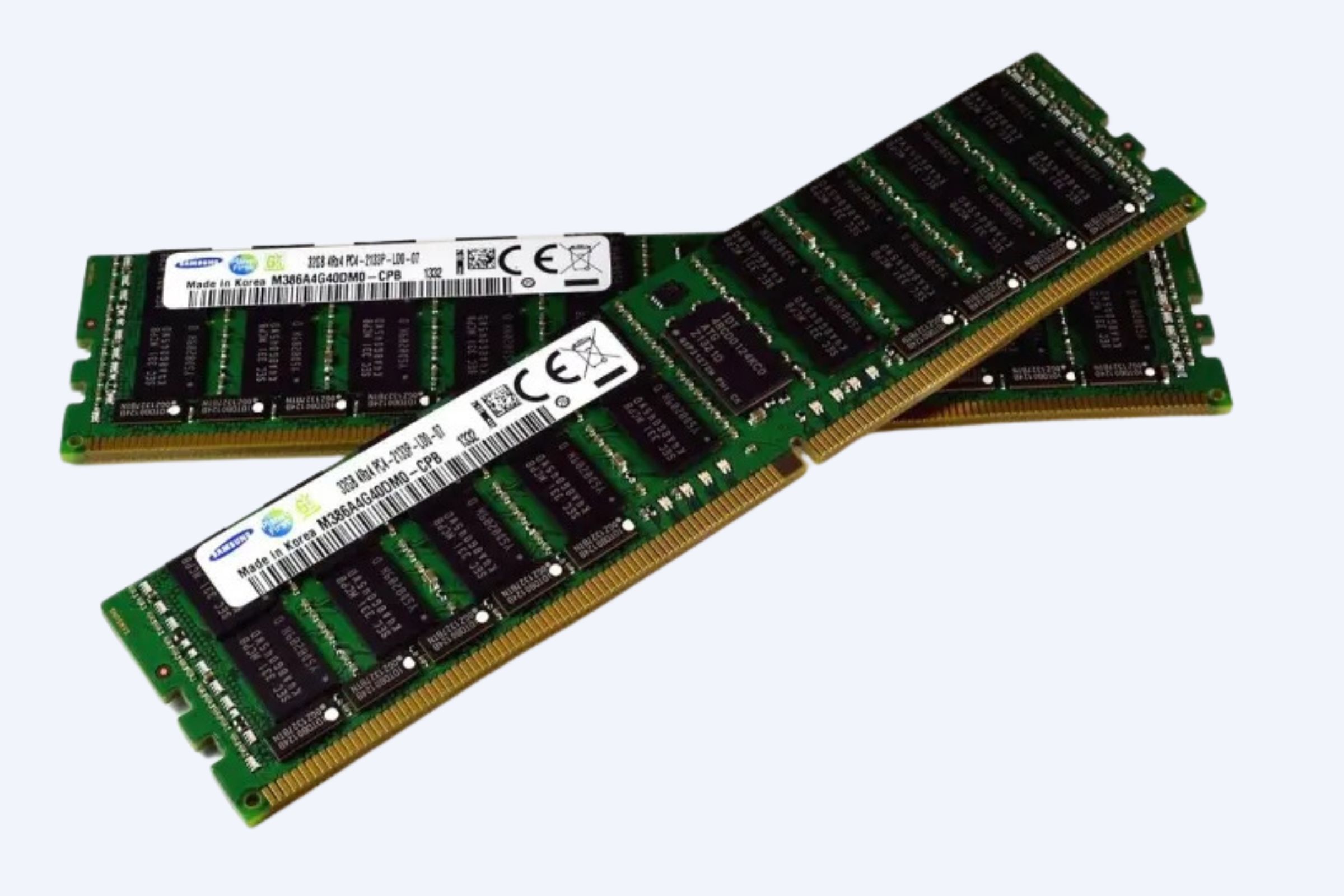

According to the International Packaging Federation (IPF), the global industrial packaging market grew 4.6% in 2025, driven by rising e-commerce logistics, IT hardware distribution, and high-value component shipping. Yet, an estimated 14% of hardware damage in transit still stems from inadequate tape sealing or slack packaging tension (McKinsey Logistics Report 2025). For IT suppliers such as WECENT — a global leader in enterprise servers, storage, and GPU distribution — even minor packaging failures can translate to substantial operational and financial losses.

As hardware value-per-unit increases, packaging integrity has become a pressing quality metric. The U.S. Bureau of Transportation found that only 70% of shipping centers verified tensile testing for sealing materials, leaving over $2 billion in damaged IT goods each year. Stretch tape adoption is now a critical focus for logistics optimization and cost mitigation.

What Are the Major Pain Points in Current Equipment Packaging?

The challenges begin with material inefficiency. Many firms rely on conventional plastic film wraps or standard adhesive tapes, both of which deteriorate under temperature fluctuations or mechanical stress. This is problematic for industries shipping heavy components like Dell PowerEdge or HPE ProLiant servers.

Another pain point is inconsistent tension. Manual wrapping often leads to uneven load distribution, exposing high-pressure zones on delicate hardware corners or GPU units. The outcome: micro-fractures, moisture infiltration, and warranty losses.

Lastly, sustainability matters. Non-recyclable or excess wrapping materials increase environmental costs, hurting brand reputation and compliance-readiness.

Why Do Traditional Packaging Materials Fall Short in Modern Logistics?

Traditional adhesive tapes depend on bonding surfaces, making them unreliable for irregular or powder-coated equipment. They loosen under vibration, humidity, and temperature changes. Plastic wraps, although flexible, fail to maintain structural stability in stacked shipments. The combination creates material waste and inconsistent sealing, increasing return rates by 8–10% for high-value shipments.

What Is the Stretch Tape Solution and How Does It Work?

Stretch tape, also known as tension film tape, uses elastic memory and mechanical grip instead of sticky adhesion. Made from linear low-density polyethylene (LLDPE) or similar polymers, it stretches up to 300% beyond its original length and reverts for a secure hold.

For IT suppliers like WECENT, stretch tape offers clean, non-residue packaging compatible with static-sensitive components — a major advantage in electronics and data center supply chains. It enables secure palletizing of servers, power storage, switches, and GPUs while minimizing material use by up to 45%.

Which Advantages Differentiate Stretch Tape from Traditional Materials?

| Feature/Aspect | Traditional Tape/Wrap | Stretch Tape Solution |

|---|---|---|

| Adhesion Mechanism | Sticky adhesive | Elastic grip (no residue) |

| Environmental Resilience | Sensitive to heat/humidity | Stable across temperature ranges |

| Recyclability | Limited | Fully recyclable LLDPE |

| Cost Efficiency | Higher material usage | Reduces tape consumption up to 50% |

| Application Flexibility | Flat surfaces only | Irregular shapes and heavy loads |

| Clean Removal | Leaves residue | No surface residue or damage |

| Load Holding Strength | Moderate | Excellent tensile tension retention |

How Can Companies Implement the Stretch Tape Process Step-by-Step?

-

Assessment: Identify packaging lines handling high-value or irregular loads.

-

Selection: Choose optimal tensile grade stretch tape for load weight. WECENT experts can guide selection based on IT hardware type (servers, GPUs, or storage).

-

Calibration: Adjust wrapping tension and overlap rate through automated or semi-automatic applicators.

-

Testing: Conduct drop, vibration, and compression tests to validate stability.

-

Integration: Train warehouse teams, optimize reel switching, and incorporate quality control monitoring.

Who Benefits Most from Adopting Stretch Tape?

The technology yields measurable benefits across verticals:

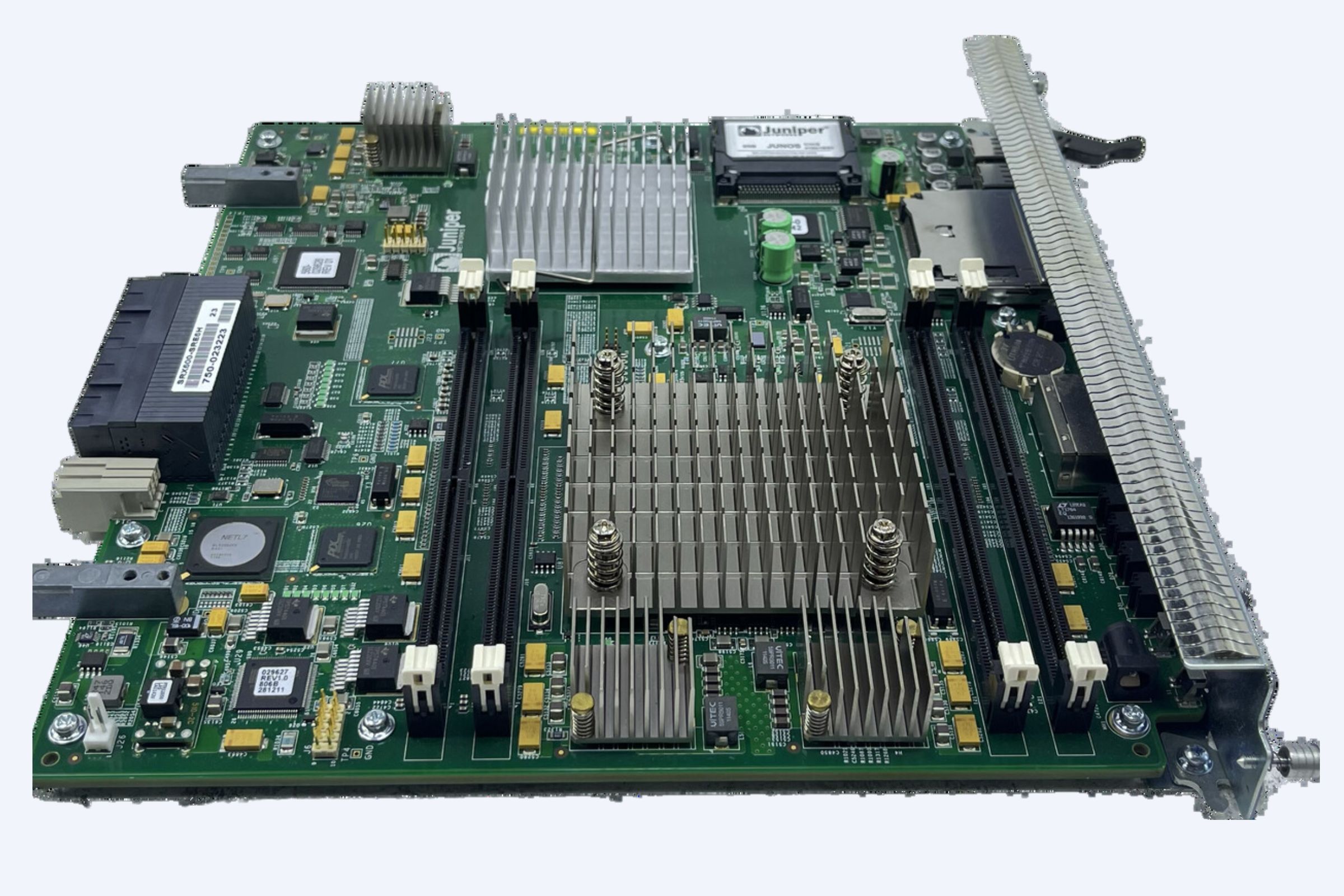

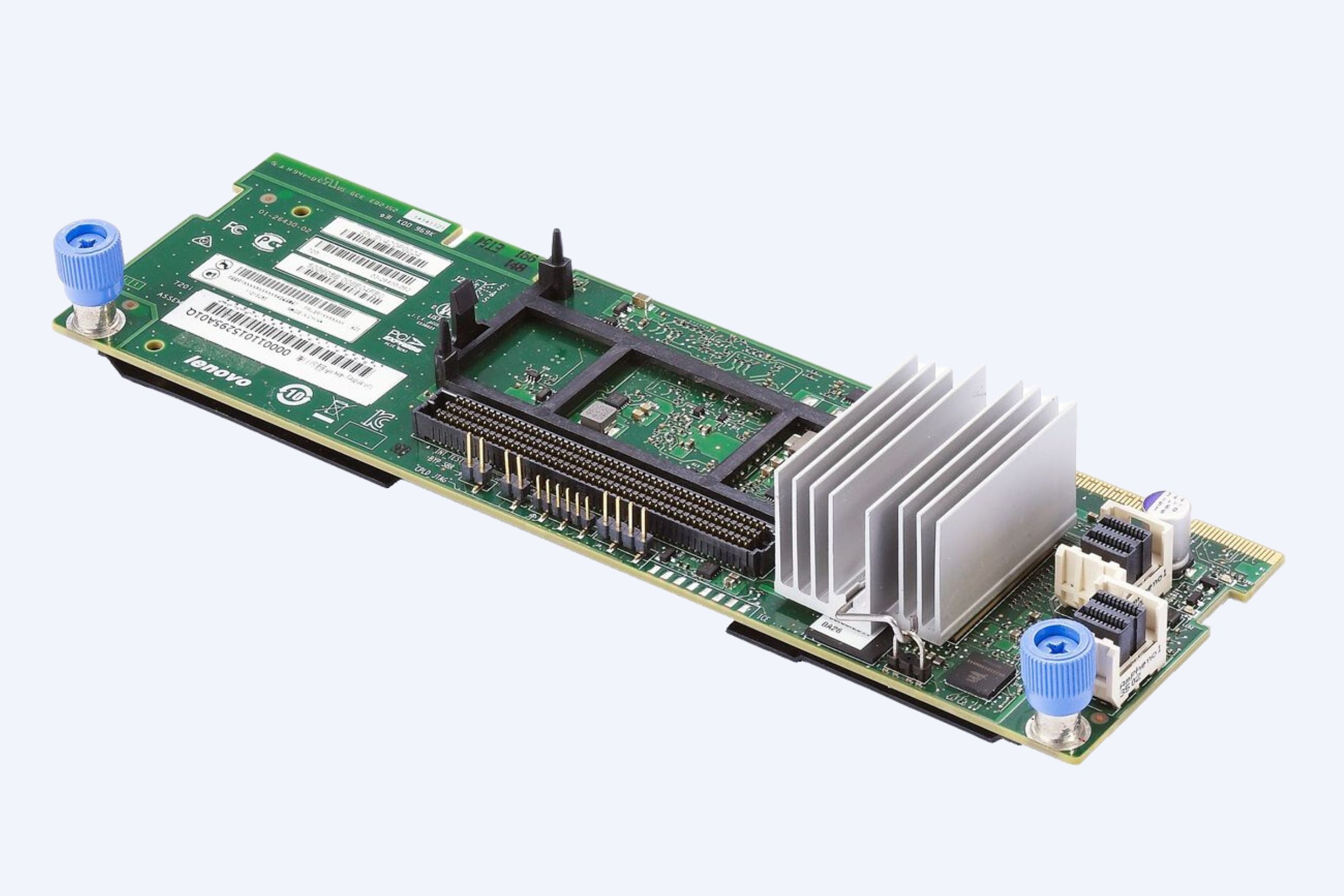

1. Data Center Equipment Shipping

-

Problem: Heavy, vibration-sensitive servers often suffer impact cracking.

-

Traditional Method: Multiple adhesive tape layers and corner reinforcements.

-

Results with Stretch Tape: Reduced packaging time by 30%, zero breakage incidents.

-

Key Benefit: Safe transit for WECENT’s Dell PowerEdge and HPE ProLiant deliveries.

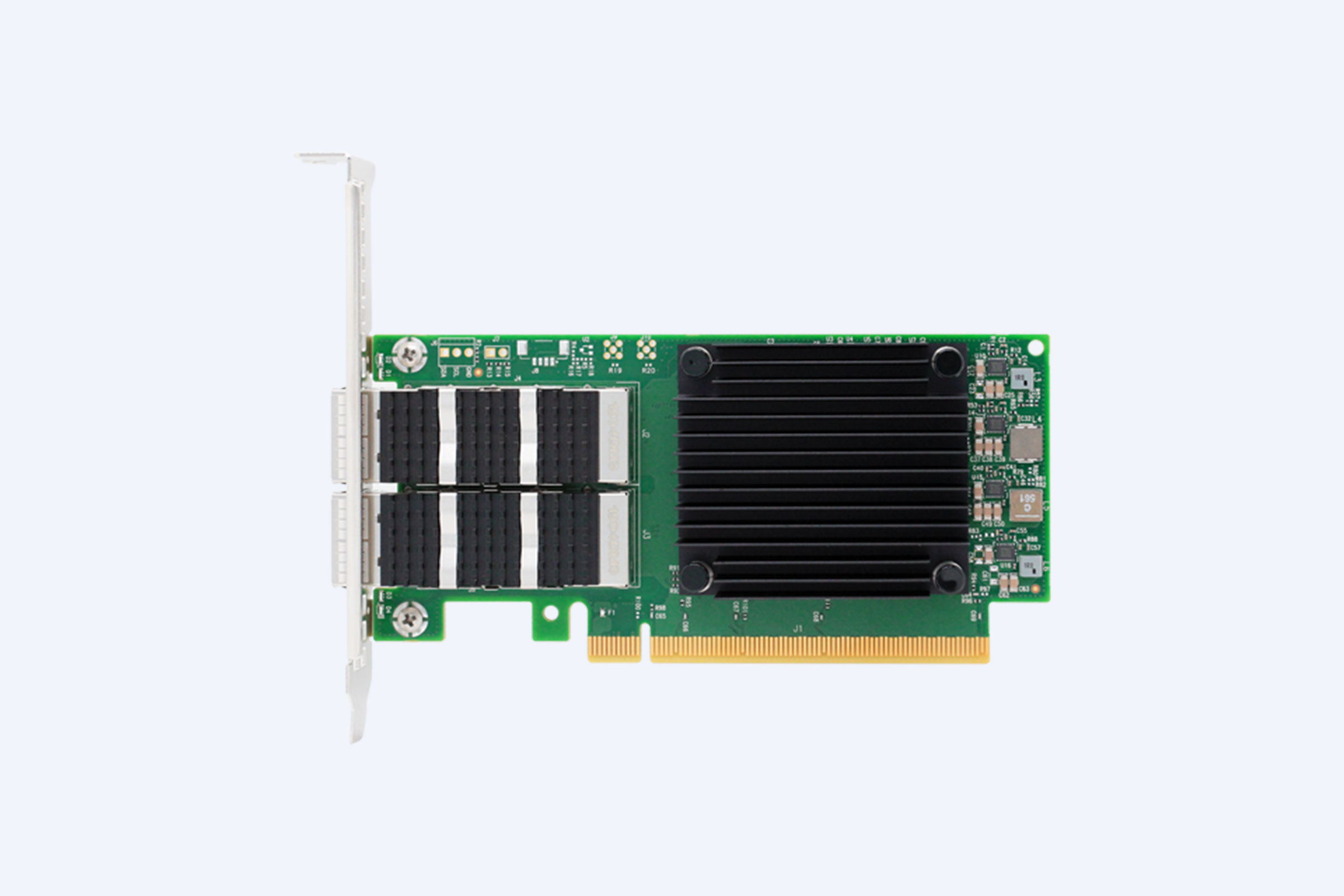

2. GPU Wholesale & Distribution

-

Problem: Temperature-sensitive NVIDIA GPU cartons lose adhesive sealing under heat.

-

Traditional Method: Reinforced adhesive with extra film.

-

Results with Stretch Tape: Stable wrapping in variable climates, reduced tape volume by 40%.

-

Key Benefit: Cleaner, eco-friendly shipments for WECENT’s RTX and Quadro product lines.

3. HPC & AI Server Export Logistics

-

Problem: Long-distance vibration impacts rackmount alignment.

-

Traditional Method: Pallet shrink wrap and strap bands.

-

Results with Stretch Tape: Improved load consistency, cut transport claims by 9%.

-

Key Benefit: Enhanced stability for enterprise and OEM partners.

4. Retail Distribution Centers

-

Problem: Labor-intensive manual taping increases cost.

-

Traditional Method: Multiple-tape sealing operations.

-

Results with Stretch Tape: 50% faster processing, ergonomic benefit reducing strain injuries.

-

Key Benefit: Streamlined automation and material savings.

Why Is Now the Best Time to Adopt Stretch Tape in Industry Logistics?

According to Statista 2026 Forecast, global LLDPE stretch tape usage will grow at a 6.8% CAGR through 2030, driven by digital equipment logistics, higher e-commerce volumes, and carbon reduction mandates. With brands like WECENT now integrating adaptive packaging technology in their IT equipment supply chain, early adopters can gain competitive edge in reliability, sustainability, and operational efficiency. The economic and environmental benefits make the transition an urgent strategic priority.

FAQ

How Is Industrial Stretch Tape Revolutionizing Equipment Protection

Industrial stretch tape provides superior equipment protection by tightly securing machinery, reducing wear and vibration, and preventing accidental damage. It improves operational safety and extends equipment lifespan. Businesses can implement it across warehouses and factories to minimize downtime. WECENT clients use these solutions to maintain high-performance IT and industrial hardware efficiently.

Can Stretch Tape Improve Machinery Storage and Safety

Using stretch tape for machinery storage prevents scratches, moisture exposure, and shifting during movement. Properly applied tape enhances stability, protects sensitive components, and simplifies inventory management. Decision-makers can integrate this method into storage protocols to ensure machinery longevity and reduce repair costs. It’s an actionable, low-cost approach trusted by industrial operators.

How Is Stretch Tape Safeguarding IT Hardware Today

IT hardware like servers, switches, and GPUs benefit from stretch tape protection against dust, vibration, and accidental bumps during transport or storage. Applying tape strategically ensures cables, drives, and chassis remain secure without compromising airflow or performance. WECENT often recommends these practices to preserve sensitive IT assets during deployment or relocation.

Can Anti-Static Stretch Tape Protect Electronics Effectively

Anti-static stretch tape safeguards electronics by preventing static discharge that can damage delicate circuits. It’s ideal for servers, GPUs, SSDs, and switches, securing components during shipping or assembly. By combining static protection with mechanical stability, businesses can reduce hardware failure risks. WECENT highlights this tape for clients managing enterprise IT infrastructure.

Is Stretch Tape the Best Choice for Heavy Equipment Packaging

For heavy equipment packaging, stretch tape offers strong adhesion, flexibility, and resistance to tearing, keeping items secure during transit. It reduces damage, prevents load shifts, and supports cost-efficient shipping. Logistics managers and industrial suppliers can implement this solution as a reliable alternative to bulk shrink wrap or fragile packaging methods.

How Does Stretch Tape Compare to Industrial Wrap in Shipping

Stretch tape is more precise than industrial wrap, allowing targeted protection for corners, edges, and delicate surfaces. While wrap covers broad areas, tape provides customized reinforcement, reducing material waste and transport damage. Businesses shipping IT or industrial assets gain control over protection strategies, combining efficiency with risk reduction.

How Can Stretch Tape Improve Equipment Maintenance Practices

Stretch tape enhances maintenance by preventing dust, moisture, and mechanical wear between servicing cycles. It supports consistent inspection routines, reduces unexpected downtime, and protects sensitive machinery or IT components. Implementing tape as a preventive measure ensures smoother maintenance workflows and prolongs asset lifespan. Decision-makers see clear ROI in reduced repair costs.

Why Is Stretch Tape a Cost-Saving Solution for Industries

Industries save by using stretch tape due to reduced equipment damage, minimized downtime, and lower replacement costs. It’s easy to apply, reusable in some cases, and compatible with diverse machinery and IT hardware. WECENT emphasizes stretch tape as a budget-friendly protective solution for enterprises seeking efficiency without compromising asset safety.