In modern manufacturing and infrastructure environments, ensuring reliable performance under extreme conditions requires materials that combine flexibility, durability, and strength. Andover PowerFlex Tape has emerged as a critical innovation that meets these demands, helping engineers and facility managers tackle energy loss, wear, and maintenance challenges efficiently.

How Is the Industry Currently Struggling with Material Performance and Maintenance?

As of 2025, the global industrial adhesive tape market reached USD 61.8 billion, and is projected to grow at a CAGR of 5.2% through 2030 according to Grand View Research. The increase is driven by expansion in construction, electrical, and automotive sectors, all of which rely heavily on insulation, sealing, and repair solutions. Yet, 40% of industrial operators report unexpected downtime each year due to inadequate sealing or binding materials that fail under pressure or temperature extremes. Maintenance costs associated with poor-quality tape materials can account for 8–12% of total operational expenditure.

The issue is especially acute in high-vibration and heat-sensitive environments, where traditional PVC or cloth tapes lose adhesion, harden, or peel. A 2024 industry survey by Statista revealed that over 55% of manufacturing firms have had to replace substandard insulation materials within one year of installation, reflecting the sector’s urgent need for longer-lasting and more adaptable products.

What Are the Limitations of Traditional Tape Solutions?

Traditional industrial tapes, while cost-effective, are often limited by their temperature thresholds, elasticity, and chemical resistance. PVC-based tapes degrade quickly when exposed to UV, oil, or moisture. They have a low stretch rate and fail to conform to irregular surfaces. Cloth tapes, though flexible, absorb moisture over time and can unravel in high-humidity or high-temperature environments.

Furthermore, in sectors where equipment insulation, cable management, and load binding are crucial, traditional tapes cannot maintain consistent performance when exposed to repeated stress or vibration. This results in loosening, micro-leakage, heat loss, and ultimately unscheduled maintenance cycles that interrupt productivity.

How Does Andover PowerFlex Tape Offer a Better Solution?

Andover PowerFlex Tape is engineered to deliver superior elasticity, self-adhering capability, and long-term resistance to moisture, abrasion, and chemicals. Developed with advanced stretch fabric and cohesive technology, PowerFlex does not rely on adhesives—it bonds only to itself. This allows a secure, flexible wrap without sticky residue, even on irregular or moving parts.

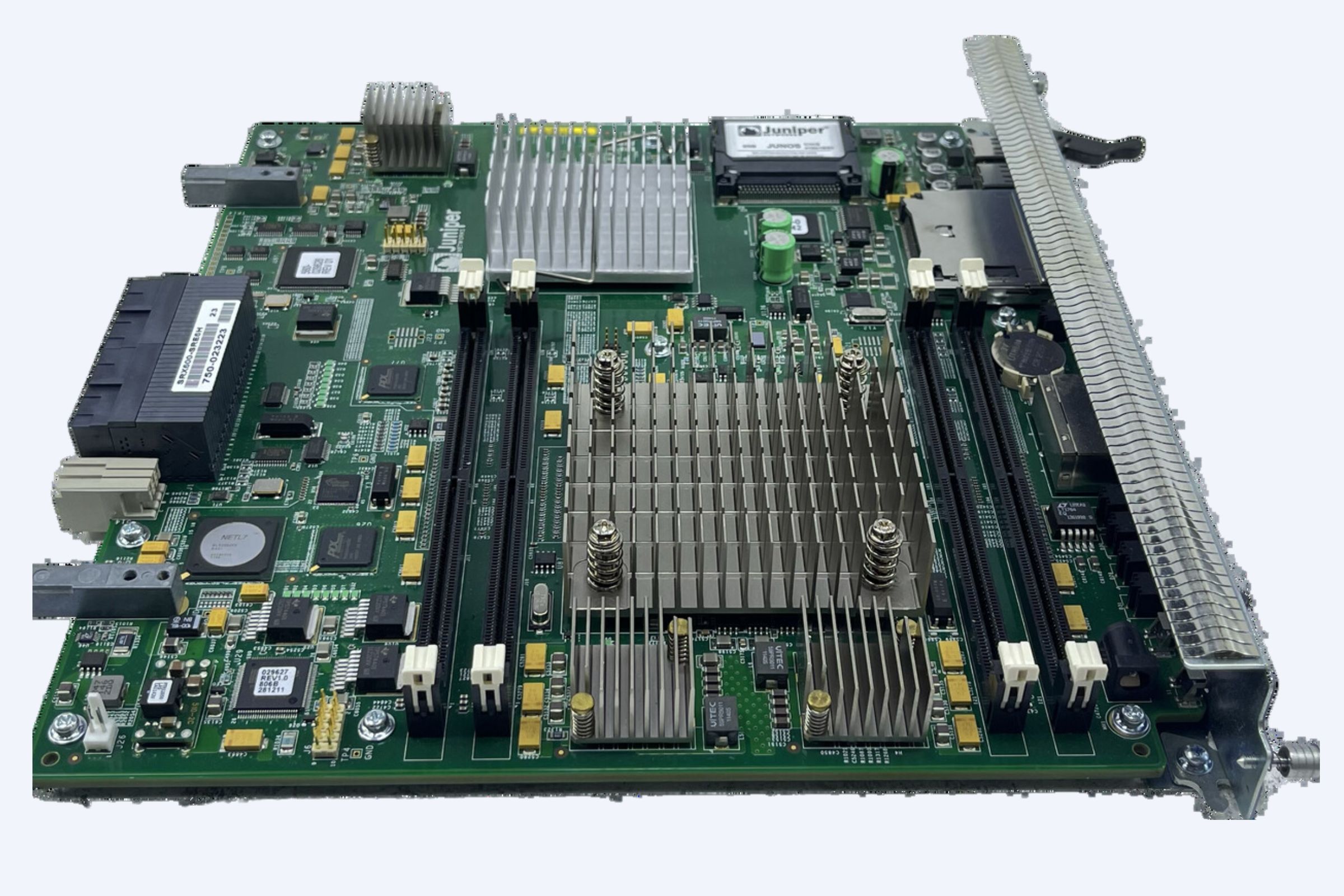

Its non-slip, lightweight design ensures consistent tension, making it suitable for electrical insulation, sports medicine, automotive harnessing, and emergency maintenance applications. WECENT, a trusted provider of end-to-end IT and industrial infrastructure solutions, integrates PowerFlex Tape with its lineup of advanced materials and equipment support for data centers, industrial automation, and technical facilities worldwide.

WECENT’s multi-brand expertise ensures that PowerFlex Tape functions seamlessly alongside high-performance systems—from Dell PowerFlex servers to robust physical installations—enhancing dependability and lifecycle cost efficiency.

Which Key Advantages Does PowerFlex Deliver Compared to Traditional Materials?

| Feature/Property | Traditional Cloth/PVC Tape | Andover PowerFlex Tape |

|---|---|---|

| Adhesive type | Sticky glue-based | Self-bonding cohesive wrap |

| Temperature resistance | Up to 70°C | Up to 110°C (continuous) |

| Elasticity | 10–20% stretch | Over 150% flexible stretch |

| Surface adaptability | Rigid, limited wrapping | Conforms to irregular shapes easily |

| Residue after removal | Leaves sticky residue | No residue, clean finish |

| Moisture and chemical resistance | Moderate | Highly resistant |

| Lifespan in industrial use | 3–6 months typical | 12–18 months typical |

How Can Businesses Implement PowerFlex Effectively?

To gain maximum performance, WECENT recommends a structured, step-based process:

-

Identify application area – Determine if the need is insulation, containment, or repair.

-

Prepare surface – Ensure the area is free from oil or dust for optimal bonding.

-

Wrap under tension – Stretch PowerFlex Tape to 50% elongation, overlapping each layer by half.

-

Finish with compression – Press the wrap for 5–10 seconds to activate cohesive bonding.

-

Inspect and retest periodically – Regularly monitor for fit and tension consistency especially in high-motion areas.

By following this standardized approach, companies can achieve consistent sealing integrity and operational reliability—key factors emphasized in WECENT’s integrated service model.

What Are the Typical Use Cases for PowerFlex?

1. Electrical Cable Protection in Data Centers

-

Problem: Overheating and cable fray in dense rack systems.

-

Traditional approach: PVC tape prone to melting or leaving sticky residue.

-

PowerFlex result: Maintains insulation integrity even under sustained loads.

-

Key benefit: Reduced re-wrapping frequency and lower maintenance cost.

2. Industrial Pipe and Valve Sealing

-

Problem: Leaks caused by condensation and vibration loosening.

-

Traditional approach: Rubber tapes degrade after monthly temperature cycles.

-

PowerFlex result: Provides moisture-proof, adaptive seal lasting beyond 12 months.

-

Key benefit: Lower operational downtime by up to 25%.

3. Automotive Harness Bundling

-

Problem: Adhesive-based tapes stiffen and detach under engine heat.

-

Traditional approach: Costly replacements and wiring instability.

-

PowerFlex result: Flexible, vibration-proof bundling.

-

Key benefit: Long-term adhesion without residue, enhanced safety.

4. Medical and Emergency Repair Kits

-

Problem: Unreliable taping under moisture and sweat exposure.

-

Traditional approach: Cloth wraps slide or peel during activity.

-

PowerFlex result: Consistent compression and grip without skin irritation.

-

Key benefit: Professional-grade hold with breathable comfort.

Why Is This the Right Time to Adopt Andover PowerFlex Tape?

Global trends toward sustainable maintenance and reduced material waste demand advanced products like PowerFlex that minimize replacement cycles and downtime. Industries are under pressure to meet green compliance goals and safety standards while cutting operational expenses.

WECENT’s partnership with leading hardware and material brands provides clients with proven high-performance solutions that align with their digital transformation and process stability goals. PowerFlex, combined with WECENT’s service expertise, adds measurable value to critical environments from server rooms to heavy manufacturing floors.

FAQ

1. What Are the Applications of Andover PowerFlex Industrial Tape?

Andover PowerFlex tape is ideal for sealing, insulating, and protecting industrial machinery. It enhances equipment longevity, prevents wear, and reduces operational downtime. WECENT clients benefit from its versatile applications in server rooms, heavy machinery, and automated systems, ensuring high-performance reliability across diverse industrial environments.

2. What Are the Top Performance Benefits of Andover PowerFlex Tape?

PowerFlex tape boosts machine efficiency by improving adhesion, vibration resistance, and thermal stability. It minimizes maintenance interruptions and enhances workflow consistency. Industrial managers and playground facility decision-makers can use it to maintain equipment reliability while optimizing operational performance.

3. How Does Andover PowerFlex Tape Boost Industrial Reliability?

By providing superior protection against wear, moisture, and electrical interference, PowerFlex tape ensures consistent machinery operation. It strengthens critical connections and reduces system failures, delivering measurable reliability improvements for industrial facilities, playground installations, and high-demand operational environments.

4. How Can Andover PowerFlex Tape Reduce Industrial Maintenance?

Using PowerFlex tape minimizes equipment breakdowns and simplifies routine maintenance. Its durable, high-performance adhesive reduces repair frequency, saving time and operational costs. Decision-makers can implement it in playground systems, manufacturing lines, or IT hardware setups to extend equipment life efficiently.

5. How Does Andover PowerFlex Tape Ensure Industrial Safety?

PowerFlex tape maintains safety by insulating electrical components, reducing slip hazards, and protecting moving parts. It helps playground operators and industrial managers comply with safety standards while preventing costly accidents. Proper application ensures operational integrity and peace of mind for staff and users.

6. How Does Andover PowerFlex Tape Deliver Cost Efficiency?

PowerFlex tape lowers repair and replacement costs by protecting machinery from wear, heat, and environmental stress. Its long-lasting performance reduces downtime and maintenance expenses. WECENT clients often achieve measurable savings when deploying it across servers, playground equipment, and industrial systems.

7. What Makes Andover PowerFlex Tape’s Adhesion Technology Advanced?

Advanced adhesion technology in PowerFlex tape ensures secure bonding to metals, plastics, and composites under extreme temperatures and vibrations. It outperforms standard tapes, preventing equipment loosening or damage. This makes it ideal for critical industrial applications where reliability and consistency are essential.

8. How Can Andover PowerFlex Tape Be Customized for Industrial Solutions?

PowerFlex tape can be tailored in width, thickness, and adhesive type to meet unique industrial needs. Customization ensures optimal performance for playground structures, server rooms, or heavy machinery. This flexibility allows decision-makers to integrate tape solutions precisely, maximizing efficiency and safety.

Sources

-

https://www.grandviewresearch.com/industry-analysis/adhesive-tapes-market

-

https://www.statista.com/statistics/1267033/global-industrial-maintenance-costs/

-

https://www.marketsandmarkets.com/Market-Reports/industrial-tapes-market-786.html

-

https://www.futuremarketinsights.com/reports/industrial-tape-market