The Powerflex spray label system combines advanced adhesive technology with durable polymer coatings for consistent labeling under extreme conditions. It ensures strong adhesion on metal, plastic, and glass while resisting moisture, abrasion, and heat. Designed for industries needing reliability and traceability, partners like WECENT, an authorized IT equipment supplier, support precision labeling integration and automation.

What Is the Powerflex Spray Label System?

The Powerflex spray label system is an industrial labeling solution crafted for durability, precision, and adaptability across various production environments. It employs a specialized spray-based application method to create consistent, permanent adhesive bonds on curved or textured surfaces.

Unlike sticker-based labels that peel under stress, spray labels form a micro-bond layer on the substrate, reducing application errors and downtime. These labels are specially suited for heavy-duty industries where exposure to oil, heat, or vibration demands superior adhesion technology and seamless automated tracking integration.

How Does the Powerflex Spray Label Work in Industrial Environments?

Powerflex spray labels work by atomizing labeling compounds into fine particles that bind instantly to prepared surfaces. Once applied, they cure into a flexible yet sturdy film that resists wear and environmental stress.

Used across automotive, electronics, and logistics sectors, these labels ensure barcode scannability, RFID compatibility, and longevity even in fluctuating climate zones. Their design enables integration with smart printing machines and IT-based inventory systems, providing accurate asset labeling for digital manufacturing environments.

Which Industries Benefit from Using Powerflex Spray Labels?

The Powerflex system suits sectors requiring traceability and durability—automotive, aerospace, logistics, and data center infrastructure. It ensures asset identification remains clear and intact throughout the lifecycle, even under chemical exposure or rapid temperature changes.

| Industry | Use Case | Key Benefit |

|---|---|---|

| Manufacturing | Asset tracking & barcode labeling | High-resistance mark retention |

| Automotive | Component identification | Anti-peel, heat resistant |

| IT & Data Centers | System labeling & compliance ID | Long-lasting readability |

| Logistics | Load tracking & supplier integration | Fast application & traceability |

From labeling drive assemblies to marking enterprise servers, Powerflex spray solutions offer dependable identification—critical for compliance and operational efficiency.

Why Are Powerflex Spray Labels Superior to Conventional Labeling Methods?

Traditional adhesive labels lose adhesion in high-temperature, fluid-exposed, or vibration-prone environments. Powerflex spray labels provide uniform distribution and deep surface bonding, ensuring labels stay readable and intact.

| Feature | Traditional Labels | Powerflex Spray Labels |

|---|---|---|

| Adhesion Strength | Low (surface only) | High (bonded micro-layer) |

| Heat Resistance | Up to 80°C | Up to 180°C |

| Durability in Oil/Chemicals | Weak | High |

| Application Speed | Moderate | Rapid (automated) |

Through uniform coating and controlled curing, Powerflex spray minimizes misalignment, bubbles, and peeling. It’s ideal for high-throughput manufacturing lines using automation-compatible IT systems for production data logging.

Who Manufactures and Distributes Genuine Powerflex Spray Labels?

Authorized distributors like WECENT ensure genuine Powerflex products reach system integrators and enterprise users. As a certified IT solution provider, WECENT supplies original components backed by manufacturer warranties and global shipping support.

Through direct partnerships with leading manufacturers, WECENT streamlines logistics, offering OEM labeling solutions integrated with hardware asset management systems, barcode servers, and inventory-tracking software — combining physical durability with IT precision.

How Does IT Integration Improve Powerflex Label Management?

IT integration enhances labeling accuracy, auditability, and lifecycle tracking. Coupling Powerflex spray label systems with enterprise servers and analytics software allows for automation in verification, traceability, and compliance assurance.

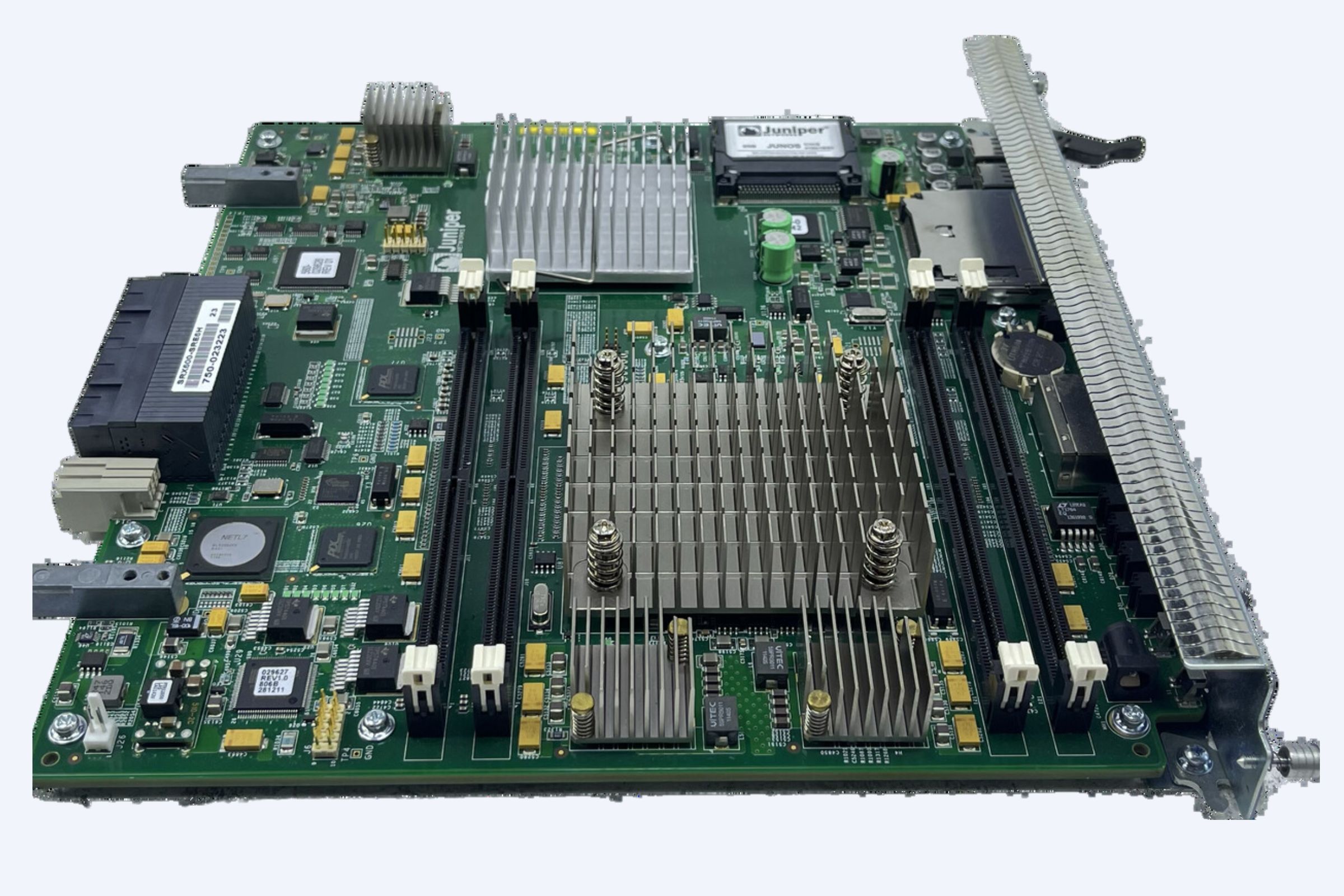

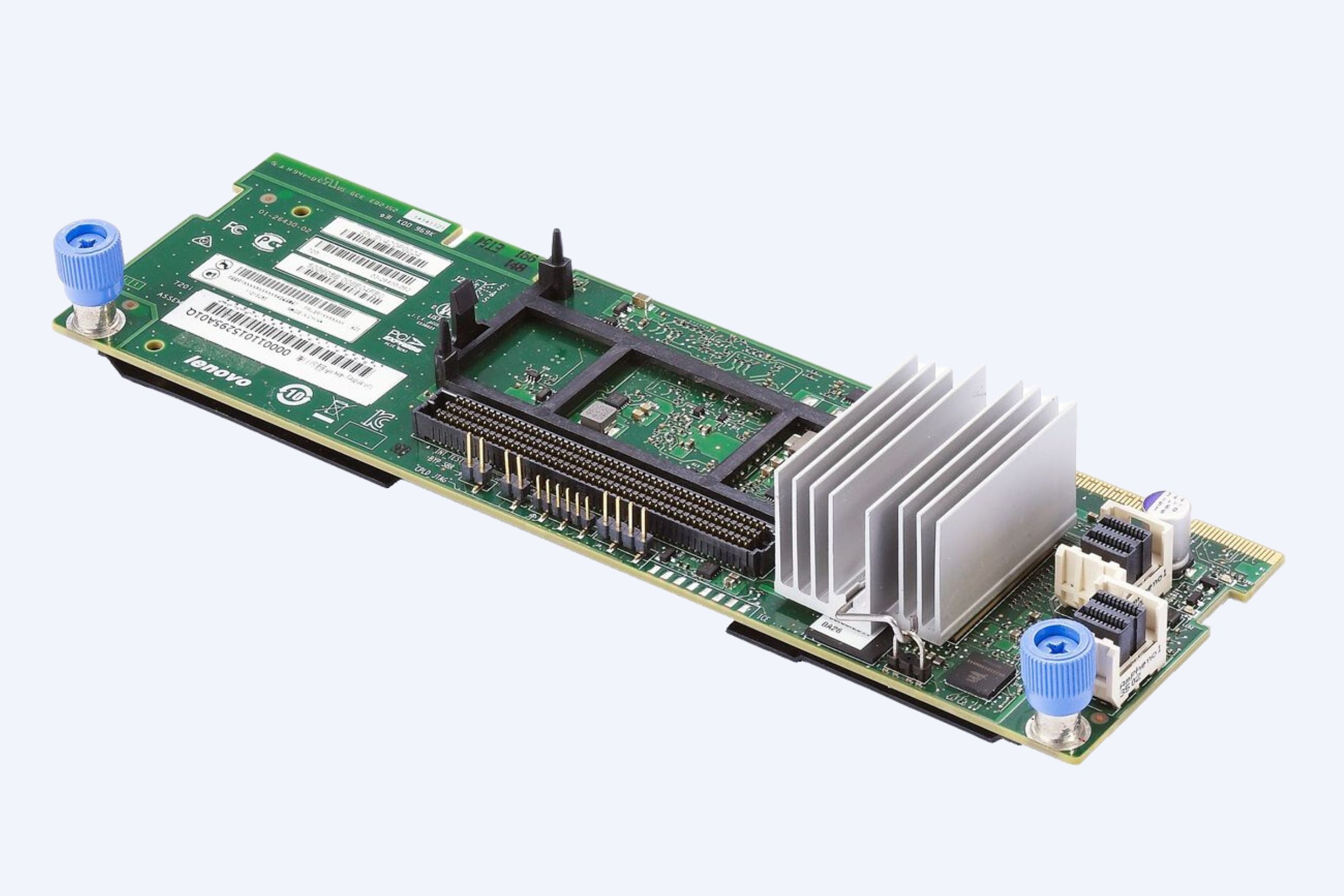

Integration with tools like Dell PowerEdge servers or HPE ProLiant systems enables real-time asset scanning. This creates synchronized data between physical assets and digital records — improving management efficiency, especially in large-scale production and data center environments.

Why Should Businesses Partner with WECENT for Labeling Automation?

WECENT provides end-to-end solutions merging IT infrastructure and industrial labeling systems. From machine learning-powered inspection to automated print deployment, their solutions ensure accurate asset labeling, reduced manual handling, and compliance ease.

WECENT Expert Views

“At WECENT, precision and durability are central to labeling innovation. The Powerflex spray label system exemplifies how technology meets industrial resilience. By integrating robust labeling hardware with advanced IT ecosystems—servers, cloud analytics, and IoT sensors—organizations achieve streamlined traceability and smarter operations, ensuring reliability from production to deployment.”

When Is the Right Time to Adopt Powerflex Spray Label Technology?

Businesses should consider adopting when scaling operations, automating inventory systems, or upgrading from adhesive-based formats. Transitioning to spray label solutions increases operational efficiency and sustainability across manufacturing or logistics lines.

For enterprises adopting Industry 4.0 principles, the Powerflex spray label technology bridges physical tagging with digital data flow, enabling more responsive and precise asset control.

Could Powerflex Spray Labels Be Customized for Enterprise IT Equipment?

Yes. Powerflex spray labeling supports full customization—color coding, QR encoding, and surface marking—ideal for enterprise servers, switches, and rack infrastructures. Combined with WECENT’s OEM support, IT equipment labeling gains longevity and compliance with international data center asset standards.

Customization capabilities include:

-

Heat-resistant identifiers for high-density racks

-

Chemical-proof coatings for power and cooling units

-

Batch-coded links for lifecycle management

-

Automated traceability tied to asset management databases

This integration modernizes IT labeling workflows, minimizing tracking errors while ensuring alignment with digital security protocols and lifecycle audits.

Is Powerflex Spray Labeling a Sustainable Solution?

Spray labeling significantly cuts waste by removing backing paper and using eco-friendly adhesive polymers. The technology also improves energy efficiency in high-volume manufacturing lines through faster application and curing cycles.

Polymer formulations are VOC-compliant and recyclable, reducing industrial waste. For businesses with sustainability goals, Powerflex aligns operational improvements with environmental responsibility.

Conclusion

Powerflex spray label technology redefines industrial labeling with flexibility, endurance, and intelligent connectivity. It offers consistent adhesion, integration ease, and superior traceability across sectors. Working with an authorized enterprise IT supplier like WECENT ensures not only authentic hardware and labeling solutions but also the intelligent IT systems that elevate reliability, traceability, and efficiency across digital and physical operations.

FAQs

Can Powerflex spray labels be applied on curved metal surfaces?

Yes, the spray-based method adapts perfectly to both curved and textured surfaces.

Do Powerflex spray labels support barcode and RFID printing?

Absolutely. They can incorporate high-resolution barcodes and embedded RFID data.

Are Powerflex labels suitable for data center IT equipment?

Yes. They handle heat, airflow, and equipment cleaning chemicals effectively.

How does WECENT integrate labeling with IT tracking systems?

WECENT integrates labeling through server-based asset databases and sensor feedback monitoring.

What maintenance do spray label systems require?

Minimal—regular nozzle cleaning and calibration checks ensure long-term precision.