Powerflex Tape is widely used for insulating, bundling, and protecting cables in high-load environments where downtime is costly. In modern IT and data infrastructure, durable tape solutions directly impact safety, uptime, and maintenance efficiency, making correct selection a measurable operational decision.

Why Is Demand for High-Performance Cable Protection Increasing?

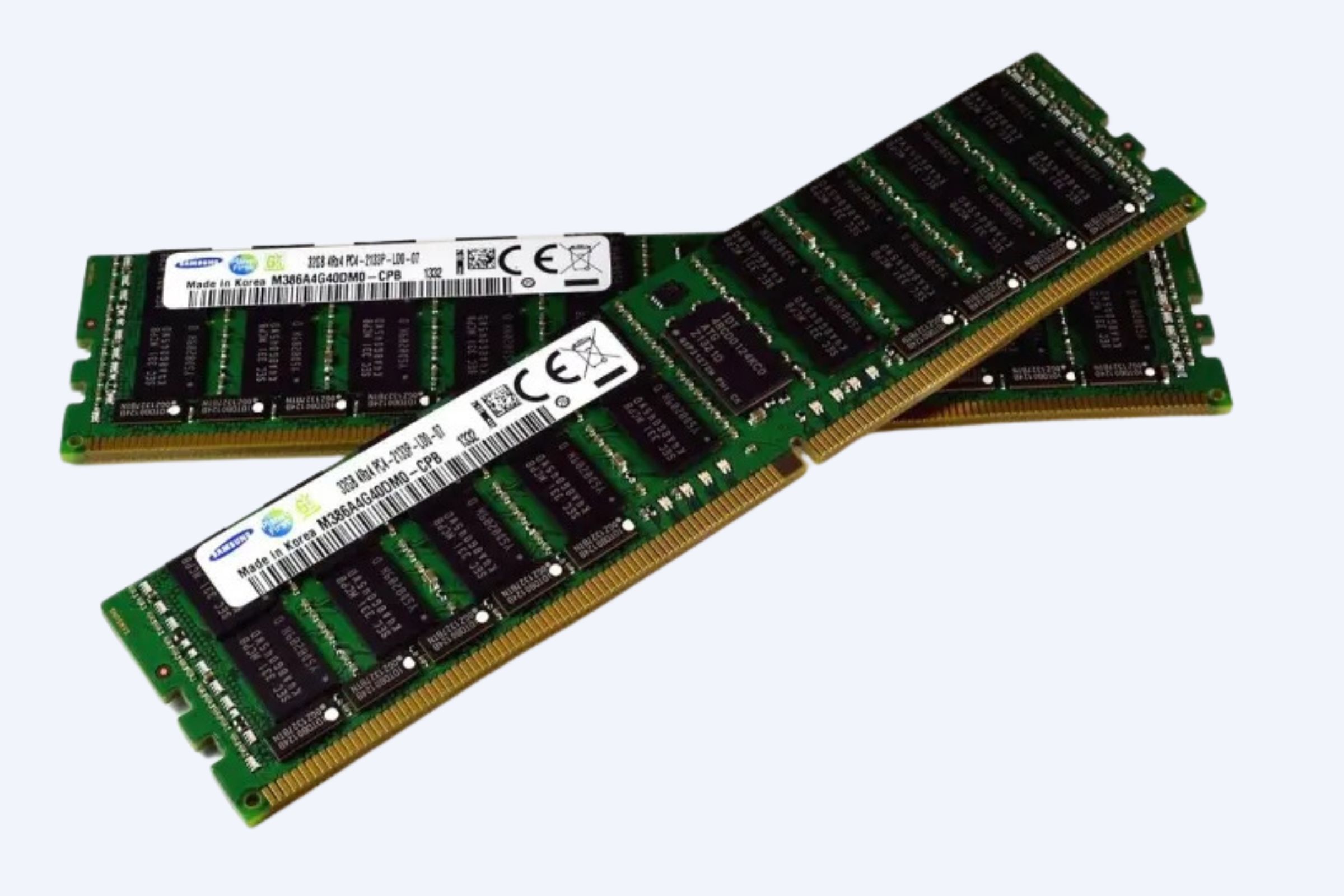

Global data center and enterprise IT infrastructure expansion is accelerating. Industry reports show that worldwide data center IP traffic has grown multiple times over the last decade and continues rising with AI, cloud, and edge workloads. Higher rack density means more cables, tighter routing, and greater thermal stress.

In high-density racks and GPU servers, cable bundles are exposed to vibration, heat, and frequent maintenance handling. Basic insulation tape often degrades, loosens, or leaves residue, increasing failure risk and service time.

Procurement teams working with enterprise hardware suppliers like WECENT increasingly specify higher-grade insulation and bundling materials as part of reliability standards.

What Operational Risks Come from Poor-Quality Tape in IT Environments?

Cable protection failures are not cosmetic — they are operational risks. Poor tape performance leads to:

-

Insulation breakdown under heat

-

Adhesive bleed contaminating connectors

-

Loose bundling causing airflow blockage

-

Increased troubleshooting time

-

Higher chance of accidental cable pullout

Studies from uptime and facilities organizations show that human error and physical layer issues contribute to a large share of unplanned outages. Weak cable management materials directly increase that exposure.

For server rooms deploying GPU clusters and storage arrays through suppliers like WECENT, physical layer reliability is now treated as a control point, not an afterthought.

How Do Traditional Electrical Tapes Fall Short?

Standard PVC electrical tapes are designed for light electrical tasks, not continuous high-stress infrastructure environments. Their limitations include:

-

Lower temperature tolerance

-

Reduced elasticity over time

-

Adhesive drying or melting

-

Residue after removal

-

Weak long-term tension holding

In dense server racks, especially those hosting AI accelerators and high-wattage components, internal temperatures and airflow velocity can exceed what generic tapes are designed to handle.

This gap creates repeated maintenance cycles and material replacement costs.

What Is Powerflex Tape and What Does It Solve?

Powerflex Tape refers to high-flexibility, high-adhesion insulation and bundling tape designed for demanding environments. It is typically engineered for:

-

High tensile strength

-

Heat resistance

-

Long-term elasticity

-

Strong adhesive stability

-

Clean removal behavior

-

Vibration tolerance

In enterprise IT deployments supported by WECENT hardware solutions, Powerflex Tape is often used for:

-

Rack cable bundling

-

Power line insulation reinforcement

-

Temporary secure fastening

-

Edge protection wrapping

-

Label and sleeve reinforcement

It acts as a low-cost but high-impact reliability layer.

Which Measurable Features Differentiate Powerflex Tape?

Key measurable characteristics buyers should verify:

-

Temperature rating range

-

Tensile strength (N/cm)

-

Elongation percentage

-

Adhesion to steel rating

-

Dielectric strength

-

Aging performance tests

-

Flame resistance certification

Procurement teams that treat tape as a spec-driven component — not a generic consumable — report lower replacement frequency and fewer cable incidents.

How Does Traditional Tape Compare vs Powerflex Tape?

| Criteria | Traditional Electrical Tape | Powerflex Tape |

|---|---|---|

| Heat resistance | Low–moderate | High |

| Elastic recovery | Weak over time | Strong long-term |

| Adhesive stability | Can dry or bleed | Stable under load |

| Vibration tolerance | Limited | Designed for motion |

| Residue after removal | Common | Minimal |

| Rack cable bundling | Temporary | Reliable |

| Lifecycle cost | Higher replacement rate | Lower replacement rate |

How Can Teams Implement Powerflex Tape in Infrastructure Workflows?

Step-by-step deployment approach:

-

Audit cable stress points in racks and trays

-

Identify high-temperature and vibration zones

-

Replace generic tape in critical paths

-

Standardize tape spec in procurement lists

-

Train technicians on tension and overlap method

-

Log replacement intervals

-

Review performance quarterly

Teams deploying enterprise servers and GPU systems through WECENT often include cable protection materials in installation SOPs to ensure consistency.

Where Does Powerflex Tape Deliver the Most Value in Real Scenarios?

Can Data Center Rack Builds Benefit?

Problem: Dense racks create cable strain and heat exposure

Traditional: Basic PVC tape loosens

After Use: Bundles stay tight under airflow

Key Benefit: Reduced cable drift and blockage

Does GPU Server Deployment Need Stronger Bundling?

Problem: Heavy power cables vibrate

Traditional: Re-taping required

After Use: Stable wrap under load

Key Benefit: Lower maintenance frequency

Who Gains in Field Network Installations?

Problem: Movement and temperature variation

Traditional: Adhesive failure

After Use: Wrap integrity maintained

Key Benefit: Fewer site revisits

Where Is It Useful in Storage and Switch Rooms?

Problem: Frequent cable tracing and changes

Traditional: Sticky residue left

After Use: Clean removal

Key Benefit: Faster reconfiguration

Why Is Now the Right Time to Upgrade Cable Protection Materials?

Infrastructure density is increasing due to AI, virtualization, and high-performance computing growth. Hardware investments are rising, but small material choices still determine physical reliability outcomes.

As organizations invest in higher-value servers, GPUs, and storage platforms through suppliers such as WECENT, supporting materials like Powerflex Tape become part of risk control and lifecycle cost optimization.

Reliable infrastructure is built from both major components and minor materials — both must meet spec.

How Do Buyers Choose the Right Powerflex Tape Specification?

Selection checklist:

-

Verify temperature rating exceeds rack conditions

-

Confirm electrical insulation certification

-

Check tensile and elongation specs

-

Require aging test data

-

Test adhesive residue behavior

-

Validate supplier consistency

-

Standardize across projects

FAQ

Can Powerflex Tape be used inside server racks safely?

Yes. High-grade Powerflex Tape is designed for heat, vibration, and electrical insulation, making it suitable for server rack cable management when temperature and dielectric ratings meet your environment specs.

Does Powerflex Tape leave residue on cables?

Quality Powerflex Tape is engineered for clean removal with minimal residue. Always verify adhesive type and aging test results before bulk deployment.

Is Powerflex Tape better than standard PVC electrical tape?

For high-stress or high-temperature environments, it typically performs better due to higher elasticity, stronger adhesion, and better heat tolerance.

Who should standardize Powerflex Tape in procurement lists?

Data centers, system integrators, and enterprise IT teams managing dense infrastructure should standardize it to reduce failure and maintenance cycles.

How often should Powerflex Tape be replaced?

In controlled environments, inspection every 6–12 months is common. Replace earlier if visual loosening, cracking, or adhesive migration appears.

Sources

Uptime Institute Annual Outage Analysis

https://uptimeinstitute.com/research-and-reports

International Energy Agency Data Centre Reports

https://www.iea.org/reports/data-centres-and-data-transmission-networks

Cisco Annual Internet Report (historical traffic growth)

https://www.cisco.com/c/en/us/solutions/executive-perspectives/annual-internet-report/index.html