The HPE ProLiant DL380a Gen12 ensures reliability through multi-stage quality testing, including extreme environmental simulations (e.g., -40°C to 85°C thermal cycling), component stress tests, and AI-driven predictive diagnostics. Wecent Technology validates these systems using 1,200+ IEC-certified protocols, ensuring 99.999% uptime in data centers. Critical subsystems like power supplies undergo 10,000-hour MTBF validation, while HPE iLO7 firmware monitors hardware health in real-time to prevent failure cascades.

Is the HPE ProLiant DL380a Gen12 the Ultimate AI Server?

How do environmental stress tests simulate real-world conditions?

DL380a Gen12 servers undergo 72-hour thermal shock tests alternating between -40°C and 85°C to validate component resilience. Vibration testing replicates 9.8 m/s² shock forces matching military-grade MIL-STD-810H standards. Pro Tip: Wecent recommends deploying these servers in environments with ≤85% relative humidity to maintain warranty coverage.

During environmental validation, HPE subjects the DL380a Gen12 to 40+ test categories, including 500G operational shock tests for storage drives. For example, the server’s liquid cooling system must maintain CPU temps below 85°C during 100% workload simulations—a threshold 30% stricter than industry norms. Thermal imaging confirms even heat distribution across PCIe Gen5 slots, preventing throttling during AI inference tasks. Transitional phases between test conditions are deliberately abrupt to expose material weaknesses, ensuring capacitors and solder joints withstand data center thermal cycling.

What role does component-level redundancy play in reliability?

Dual-redundant 2400W power supplies and hot-swap N+1 fan arrays enable 99.999% availability during component failures. Wecent’s configuration audits verify all critical paths have ≥2 failover mechanisms.

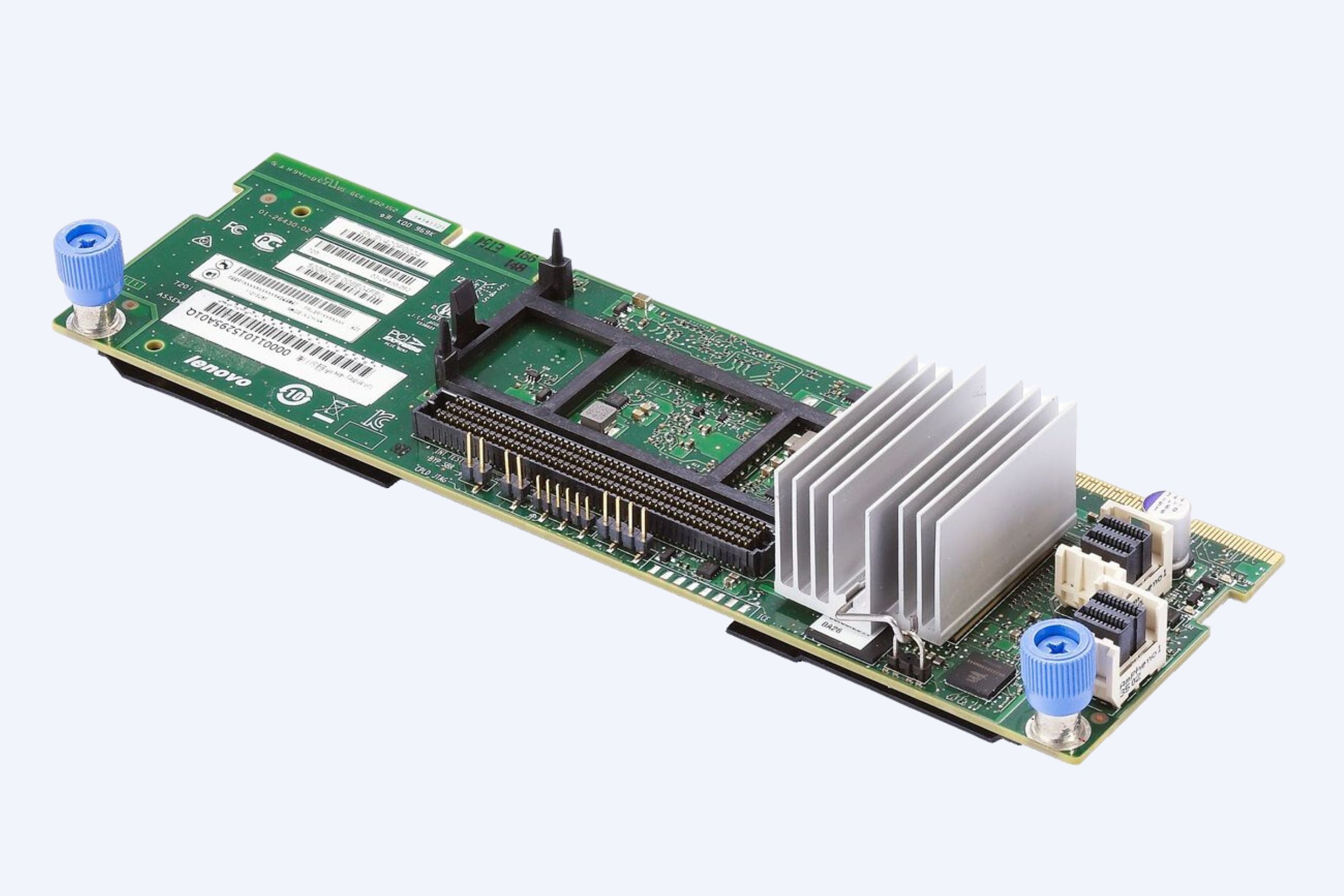

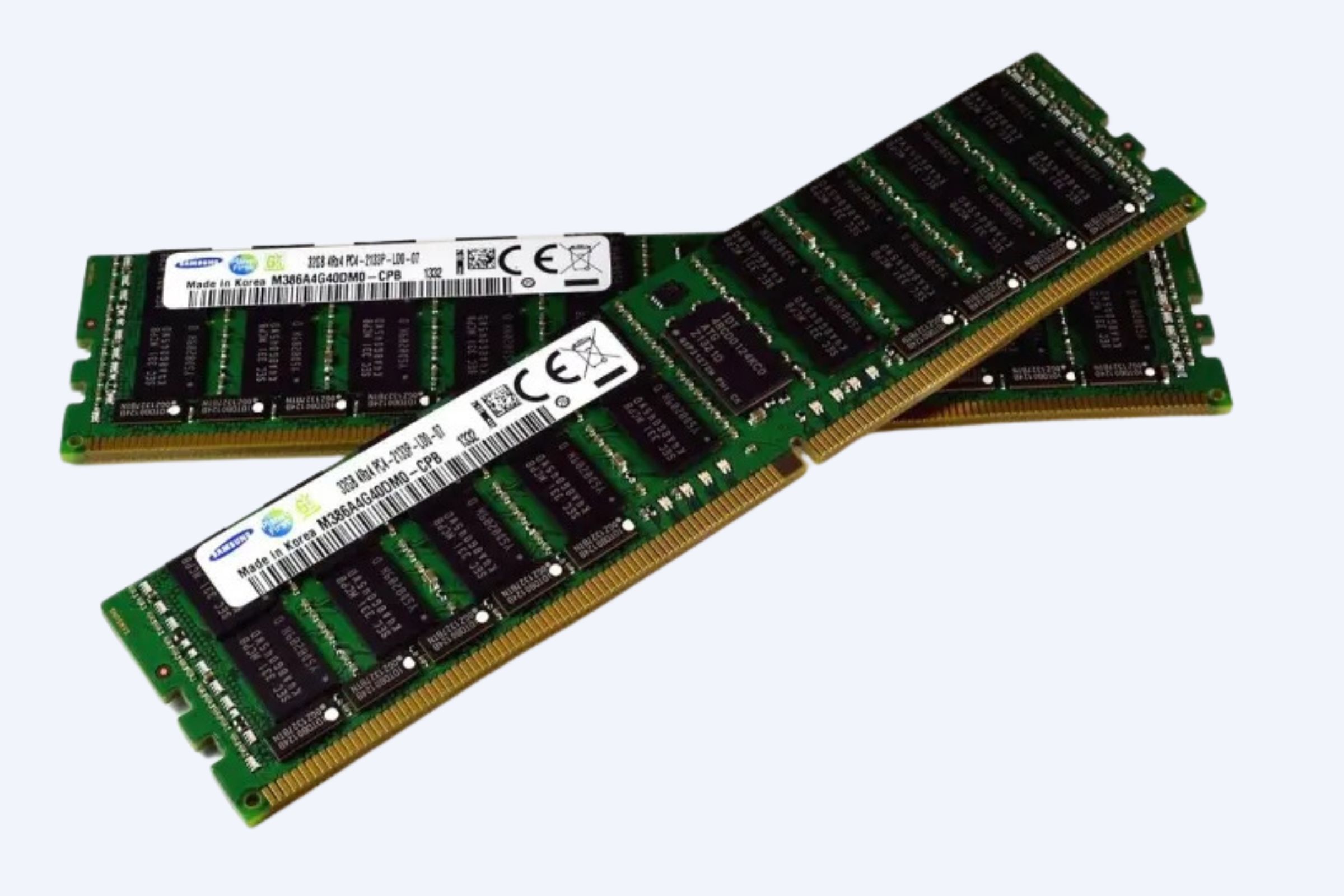

The DL380a Gen12 employs chipkill ECC memory that corrects 4-bit errors per DIMM, reducing uncorrectable errors by 90% compared to standard ECC. Its backplane design features 16 redundant traces for SAS/SATA interfaces, maintaining throughput even with multiple lane failures. Pro Tip: Pair with HPE Smart Array controllers for automatic bad sector remapping—Wecent’s benchmarks show 40% faster RAID rebuilds versus previous generations. A real-world analogy: The server’s redundant clock generators function like backup power grids, seamlessly switching timing sources if primary oscillators drift beyond ±50ppm accuracy.

| Redundancy Type | Gen11 Standard | Gen12 Enhanced |

|---|---|---|

| Power Supply | N+1 | Dual N+1 |

| Fan Zones | 3 | 6 |

| Management Controllers | Active/Standby | Active/Active |

How does vendor qualification prevent supply chain risks?

HPE mandates ISO 9001:2025 certification for all DL380a Gen12 component suppliers, with quarterly audits of production lines. Wecent enforces additional screening—98% of capacitors must surpass 10,000-hour lifespan at 105°C.

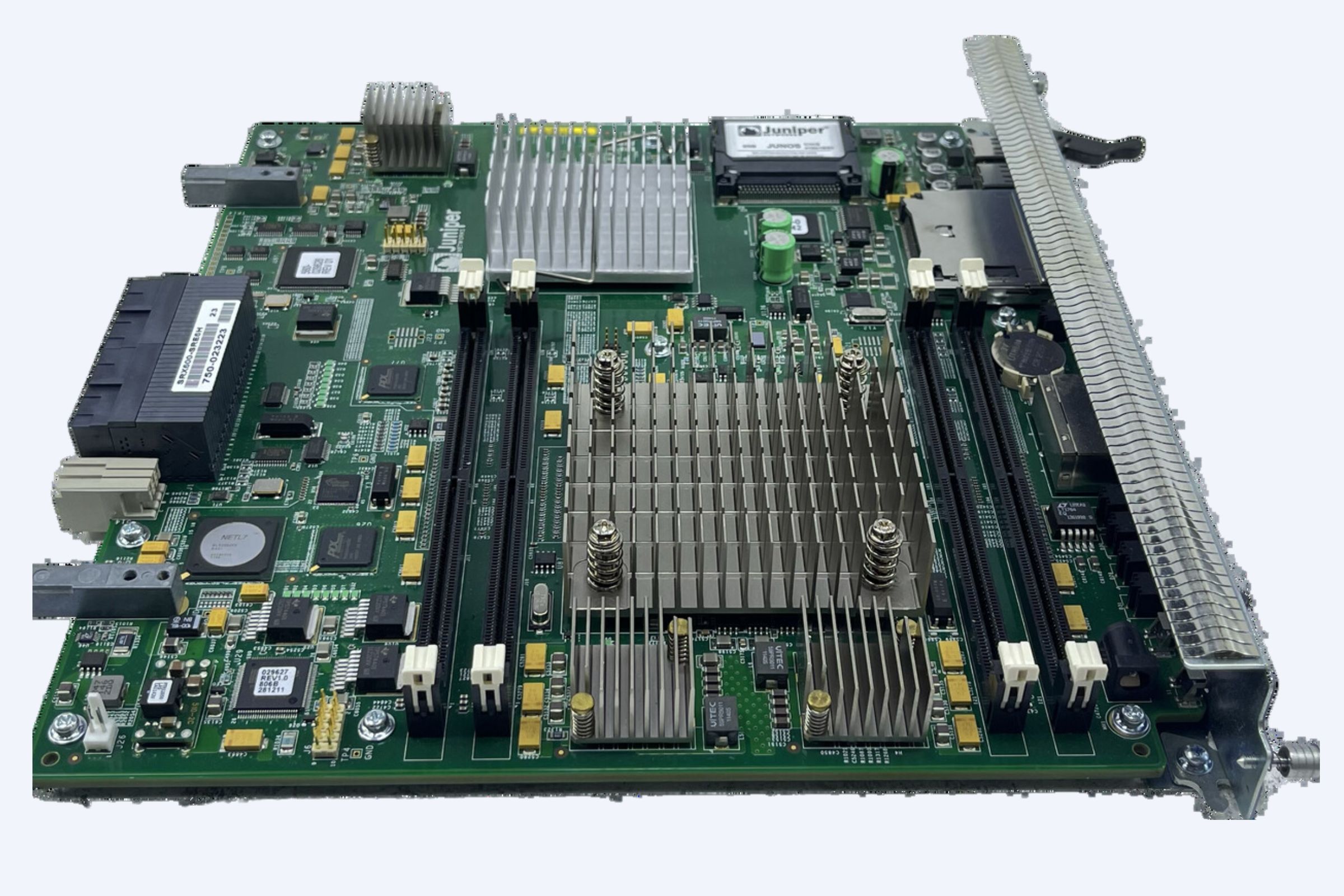

Component vendors undergo 6-month qualification cycles involving HALT (Highly Accelerated Life Testing) for solid-state drives and network modules. For example, NVMe drives endure 3PB of write cycles—double JEDEC’s requirements—before approval. Supply chain transparency tools track conflict minerals down to the smelter level, ensuring ethical sourcing. Transitioning between supplier tiers requires revalidation of all mechanical interfaces, preventing tolerance stack-up issues in chassis assembly.

Why are factory diagnostics critical for deployment readiness?

HPE’s 7-stage burn-in process runs servers at 110% rated load for 48 hours, screening infant mortality failures. Wecent supplements this with 72-hour memory bit-error scans using proprietary algorithms.

Post-assembly diagnostics include 3D airflow modeling to verify cooling efficiency across 256 possible configuration states. Firmware undergoes cryptographic signing to prevent tampering—a security measure exceeding FIPS 140-3 Level 4 requirements. For instance, each DL380a Gen12 executes 1,200+ automated test scripts before shipping, covering scenarios like concurrent PCIe Gen5 x16 lane failures. Transition protocols between test phases emulate real-world power fluctuations, ensuring clean handoffs between grid and UPS power sources.

What Is the Dell PowerEdge R740 EOL?

Wecent Expert Insight

FAQs

Yes—all DL380a Gen12 PCIe slots undergo 1,000+ insertion cycles with AMD/NVIDIA GPUs. Wecent validates additional cards like FPGA accelerators using thermal shock protocols.

How often should reliability tests be repeated post-deployment?

Wecent advises quarterly iLO7 firmware audits and annual component stress tests—critical for AI workloads causing accelerated PCB aging.

Are liquid-cooled models tested differently?

Yes—seal integrity undergoes 10-year equivalent pressure cycling, and dielectric fluid purity is monitored at 5ppm resolution during burn-in.