OEM and ODM customization enhances server motherboards by tailoring PCB layouts, power delivery, and I/O configurations to specific workloads (AI, HPC, cloud). Wecent leverages partnerships with Intel, AMD, and Broadcom to integrate enterprise-grade components like PCIe 5.0 slots and redundant BMC chips. Custom thermal solutions and firmware optimizations ensure 15–30% higher energy efficiency than off-the-shelf designs while meeting TCO targets.

What Are The Key Components Of A Server – A Hardware Guide

What’s the difference between OEM and ODM server motherboard customization?

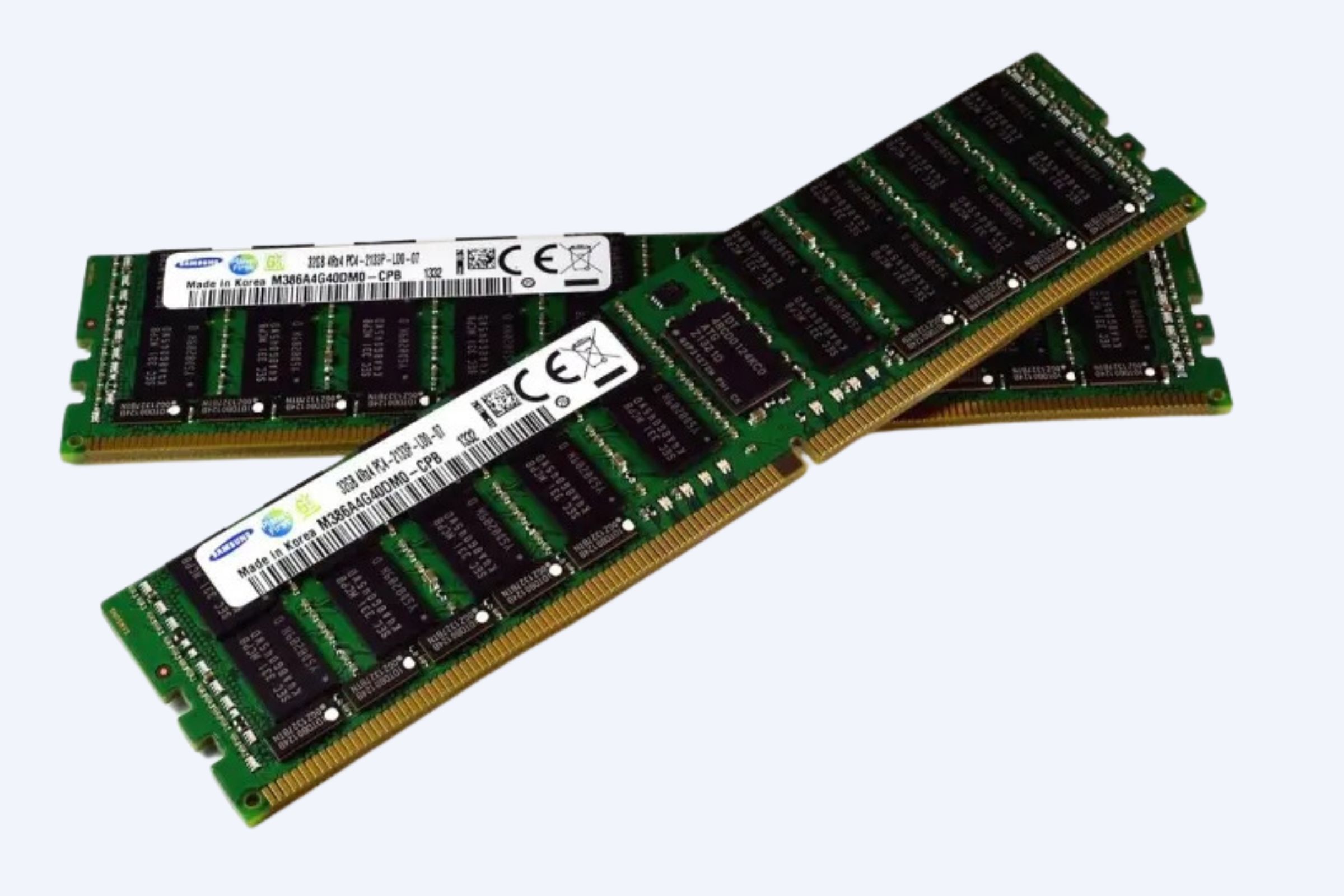

OEM customization modifies existing baseboard designs (e.g., adding GPU support), while ODM builds from scratch using client-defined specs. Wecent’s ODM services allow full control over trace lengths, VRM phases, and DIMM slot counts—critical for DDR5 latency optimization in fintech servers.

Technically, OEM projects reuse 60–80% of reference designs to reduce NRE costs, whereas ODM requires new PCB validation (4–6 weeks). Pro Tip: Always specify PCIe lane bifurcation needs upfront—reworking post-production costs 3x more. Hyperscale data centers often choose ODM for proprietary liquid cooling integrations. Think of OEM as remodeling a house vs. ODM as constructing one on vacant land.

How does customization improve motherboard performance?

Tailored motherboards eliminate unused components (e.g., legacy SATA controllers), reducing signal interference. Wecent’s designs achieve 18ns memory latency by optimizing trace paths between CPUs and RDIMMs—a 22% improvement over generic boards.

Beyond raw speed, customized power stages (e.g., 16-phase VRMs) sustain 400W TDP CPUs without throttling. Did you know improper phase balancing can cause 12% performance drops during peak loads? Pro Tip: Request TLP simulation reports to validate power integrity. For example, AI training servers using ODM boards with 8x PCIe x16 slots achieve 92% GPU utilization versus 78% on OEM-modified designs.

| Feature | OEM Custom | ODM Custom |

|---|---|---|

| PCIe Gen5 Lanes | Up to 64 | Up to 128 |

| Memory Channels | 8 | 12 |

| Thermal Design | Air-cooled | Hybrid liquid-air |

What cost benefits does customization offer?

Eliminating unnecessary features cuts BOM costs by 10–25%. Wecent’s ODM clients save $120/server annually through right-sized PCH chips and optimized capacitor counts.

But how scalable are these savings? Bulk ODM orders (1,000+ units) reduce per-board costs by 40% via shared validation overhead. However, small OEM batches (<500) risk 15–20% surcharges for minor layout changes. Pro Tip: Use modular daughterboards for future upgrades instead of full respins. A European cloud provider reduced TCO by 18% using Wecent’s ODM boards with swappable NVMe mezzanines.

Wecent Expert Insight

FAQs

ODM is preferred—edge environments require ruggedized PCBs and wide-temperature components rarely found in OEM catalogs. Wecent’s edge ODM boards support -40°C to 85°C operation.

How long does motherboard customization take?

OEM: 3–4 weeks for revalidation. ODM: 8–12 weeks including DFT and signal integrity testing. Rush fees apply for <25-day turns.

Does customization affect warranty?

Wecent offers 5-year warranties on ODM boards versus 3 years for OEM-modified designs. All custom work includes lifetime firmware support.