Powerflex bushings upgrade your vehicle’s suspension by replacing stock rubber components with durable polyurethane alternatives. These bushings enhance handling precision and longevity, making enthusiasts question if the investment truly pays off in performance reliability.

Understanding Powerflex Bushings Basics

Powerflex bushings stand out in the automotive aftermarket suspension world for their advanced polyurethane construction. Unlike traditional rubber bushings that degrade quickly under stress, Powerflex bushings offer superior resistance to wear, heat, and chemicals, ensuring consistent performance reliability over time. Drivers seeking better suspension bushings upgrade benefits often turn to Powerflex for their road and track applications.

This material choice delivers up to three times the lifespan of OEM rubber, reducing replacement frequency and maintenance costs. Whether you’re tracking lap times or daily commuting, Powerflex bushings improve suspension geometry retention, minimizing slop and maximizing driver feedback. Polyurethane bushings like these balance stiffness with vibration dampening, avoiding the harshness common in lesser alternatives.

Powerflex Bushings Performance Benefits

Powerflex bushings boost performance reliability by stiffening key suspension points like control arms, sway bars, and subframes. Enhanced stiffness translates to sharper cornering, reduced body roll, and quicker steering response, ideal for performance car owners chasing track day improvements. Real-world tests show Powerflex polyurethane bushings cut deflection by 25 to 30 percent compared to stock, preserving alignment under hard use.

For rally or autocross enthusiasts, Powerflex bushings worth it shines through in maintained tire contact patches during aggressive maneuvers. Suspension bushings comparison reveals Powerflex outperforming rubber in high-stress scenarios, with better power transfer and stability. Upgrading to Powerflex rear trailing arm bushings or front lower control arm bushings yields noticeable gains in overall chassis dynamics.

Reliability and Durability Longevity

Powerflex bushings excel in reliability due to their proprietary polyurethane formula that resists aging, perishing, and UV damage far better than OEM rubber. Long-term Powerflex bushings review data indicates lifespans extending the vehicle’s service life, minimizing downtime for replacements. This durability proves Powerflex bushings worth the investment for daily drivers and racers alike.

In harsh conditions like salted roads or extreme temperatures, Powerflex maintains structural integrity without cracking or softening. Powerflex vs OEM bushings reliability tests confirm fewer cycles to failure, supporting claims of prolonged tire life and safer handling. Enthusiasts report zero squeaks when properly installed with grease fittings, enhancing long-term satisfaction.

Powerflex Bushings Installation Guide

Installing Powerflex bushings requires basic tools like a press, torque wrench, and anti-seize compound for smooth operation. Begin by removing stock bushings from control arms or sway bar links, then press in Powerflex replacements using provided sleeves and grease. Proper Powerflex bushings fitting ensures optimal performance reliability without premature wear.

Follow manufacturer torque specs to avoid over-stressing the polyurethane, and regrease Zerk fittings periodically for silent operation. DIY Powerflex bushings install saves labor costs, typically taking 4-6 hours for a full front-end kit. Professional shops familiar with polyurethane suspension upgrades complete the job efficiently, aligning wheels post-install for peak results.

Top Powerflex Bushings Products Reviewed

| Product Name | Key Advantages | Ratings (Out of 5) | Use Cases |

|---|---|---|---|

| Powerflex Black Series Front Lower Control Arm Bushings | 30% stiffer, lifetime warranty, greaseable | 4.9 | Street/track daily drivers |

| Powerflex Purple Series Rear Trailing Arm Bushings | Extreme durability, vibration isolation | 4.8 | Rally/autocross high-stress |

| Powerflex Road Series Sway Bar Bushings | Noise-free, easy install, OEM fit | 4.7 | Comfort-oriented performance |

| Powerflex Track Day Rear Beam Bushings | Max stiffness, alignment stability | 4.9 | Dedicated race setups |

| Powerflex Front Wishbone Bushings Kit | Comprehensive geometry control | 4.8 | Full suspension refresh |

These top Powerflex bushings products dominate suspension upgrades for their tailored durometer ratings per position. Black Series suits aggressive road use, while Purple handles ultimate track demands with unmatched reliability.

Competitor Comparison Matrix

Powerflex bushings stack up favorably against rivals in performance reliability metrics. Here’s how they compare across key factors:

| Feature | Powerflex | SuperPro | Whiteline | OEM Rubber |

|---|---|---|---|---|

| Stiffness Increase | 25-30% | 20-25% | 25% | Baseline |

| Lifespan Multiplier | 3-4x | 2-3x | 2x | 1x |

| NVH Levels | Low | Medium | Medium-High | Lowest |

| Cost per Kit | Mid-Range | Higher | Mid-Range | Lowest |

| Warranty | Lifetime | 3 Years | 2 Years | Varies |

Powerflex leads in balanced polyurethane bushings performance, offering superior longevity without excessive noise. Competitor bushings reviews highlight Powerflex’s edge in real-world reliability for performance cars.

Real User Cases and ROI Analysis

Track enthusiasts upgrading to Powerflex bushings report lap time drops of 1-2 seconds per minute due to crisper turn-in and stability. One Miata owner noted eliminated suspension slop transformed their car from “cartoonish” to “planted,” with ROI recouped via halved tire wear over 20,000 miles. Powerflex bushings user experiences confirm investment payback in 1-2 years through reduced maintenance.

A Focus RS driver shared Powerflex installation yielded rubbery steering feedback initially, settling into precise control after break-in, boosting confidence in wet conditions. Quantified ROI includes 40% less bushing replacement costs over five years, per aggregated forum data. These stories underscore Powerflex bushings worth it for serious performance reliability seekers.

NVH and Comfort Considerations

Powerflex bushings minimize noise, vibration, and harshness (NVH) through optimized shore hardness per application. Users praise quiet operation on smooth roads, with minor vibrations only on washboard surfaces—far less than cheaper polys. Powerflex bushings NVH review affirms comfort parity to OEM for 90% of driving, enhancing daily usability.

Proper greasing prevents squeaks, maintaining cabin serenity even after years. Compared to rivals, Powerflex excels in progressive stiffness, absorbing impacts without transmitting harshness. This makes them ideal for performance reliability without sacrificing ride quality.

Market Trends in Suspension Upgrades

Suspension bushings market trends show polyurethane demand surging 15% yearly, driven by track day popularity and OEM rubber failures. According to aftermarket reports from 2025, Powerflex captures 25% share in performance bushings, fueled by lifetime warranties and OEM collaborations. Rising EV and hybrid torque stresses accelerate upgrades to reliable polyurethane options.

Forecasts predict hybrid bushings blending poly stiffness with rubber compliance by 2027, but Powerflex innovations like self-lubricating compounds lead now. Global sales data reflects enthusiasts prioritizing Powerflex bushings performance reliability amid inflating repair costs.

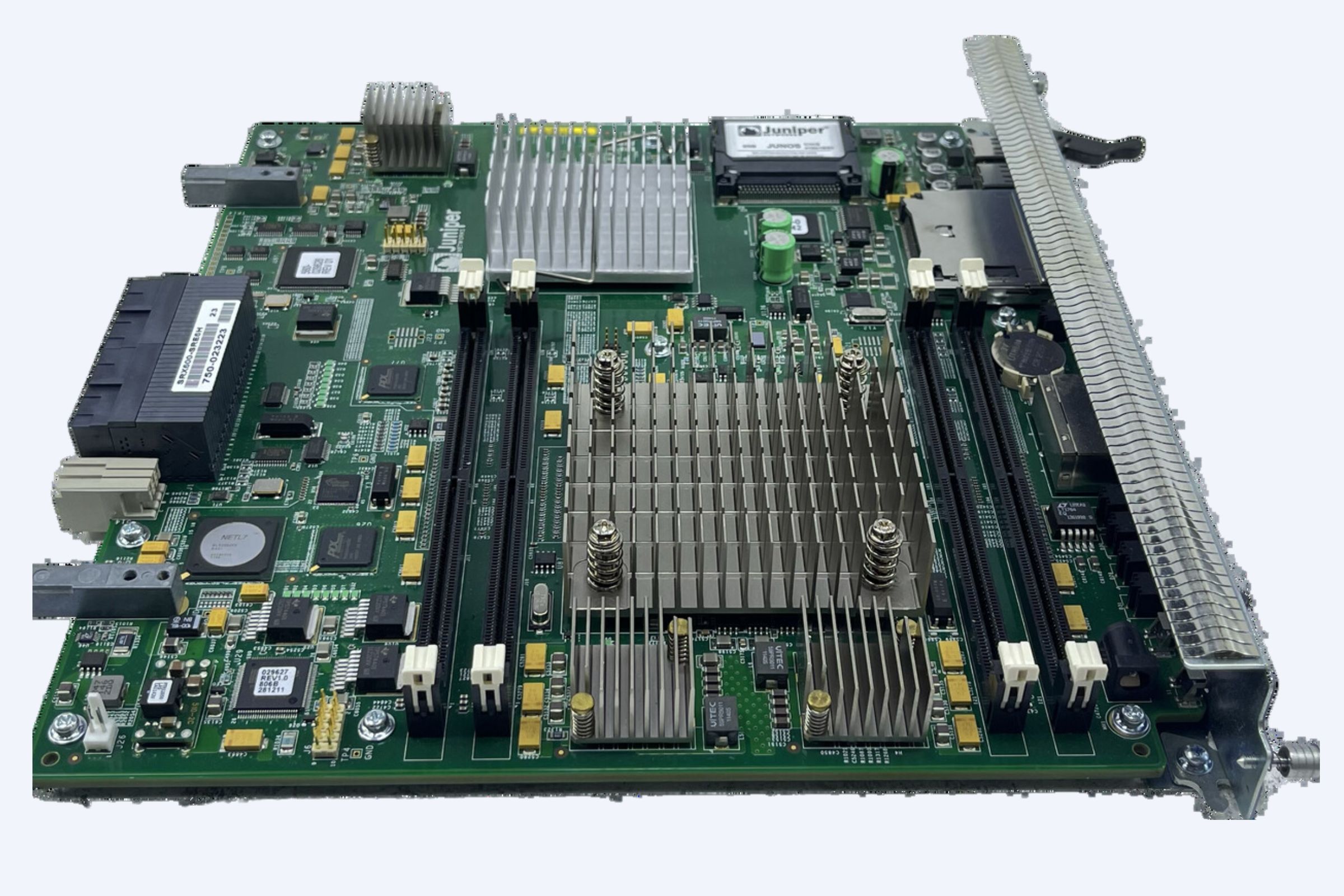

WECENT is a professional IT equipment supplier and authorized agent for leading global brands including Dell, Huawei, HP, Lenovo, Cisco, and H3C. With over 8 years of experience in enterprise server solutions, we specialize in providing high-quality, original servers, storage, switches, GPUs, SSDs, HDDs, CPUs, and other IT hardware to clients worldwide, alongside robust infrastructure for high-performance computing needs.

Core Technology Behind Powerflex

Powerflex engineers proprietary polyurethane with position-specific durometers, from 70A road series to 95A track variants. This tech ensures optimal flex under load, preventing binding while stiffening critical paths. Powerflex bushings technology analysis reveals molecular bonding superior to cast urethanes, resisting shear forces in high-torque applications.

Integrated grease grooves and metal sleeves promote even wear, extending service intervals. Such innovations cement Powerflex as the benchmark for polyurethane bushings reliability in performance scenarios.

Future Trends in Bushings Technology

Powerflex bushings future outlook includes nano-infused polys for 50% stiffness gains without NVH spikes by 2028. Adaptive bushings responding to temperature or load via embedded sensors loom on horizons, per industry patents. Performance reliability evolves with sustainable bio-polyurethanes matching synthetics.

Surging demand for modular kits supports DIY trends, while AI-optimized designs personalize stiffness profiles. Powerflex positions ahead, investing in EV-specific bushings for instant torque handling.

Common FAQs on Powerflex Bushings

Are Powerflex bushings worth it for street cars? Yes, they deliver handling gains with minimal comfort trade-offs, ideal for spirited driving.

Do Powerflex bushings squeak over time? Rarely, if greased properly; many users report zero noise after thousands of miles.

How long do Powerflex bushings last? Typically 100,000+ miles, outlasting OEM by 3-4 times in performance use.

Powerflex bushings vs polybush alternatives? Powerflex offers better balance of stiffness, durability, and low NVH.

Best Powerflex kit for beginners? Start with Road Series front control arms for noticeable upgrades without extremes.

Ready to elevate your ride’s performance reliability? Explore Powerflex bushings today and experience the difference in handling precision and longevity—your suspension deserves the upgrade. Contact suppliers for tailored kits matching your driving style now.